Contamination of Gear Box and the Journal Assembly |

|

| Contamination is a major problem faced by owners of RAYMOND CE Mills all around the world. |

Contamination causes Mill outages and apart from direct loss in generation due to non-availability of mills, the cost of repairs / replacement and cost of internals, bearings, lube oils etc. of Gear Box & Journal Assly runs into millions of Dollars.

|

| Contaminants are Pulverized Fuel (PF),rejects and ash/dust. Carriers of the contaminants are Primary Air (PA) and Seal Air (SA). Both these contaminants are highly abrasive. PA is hot and at a higher pressure than that of SA. |

Contamination occurs when contaminants go across the Shaft and the Rubber Seals around them and mix with the Lube Oil in the Gear Box/Journal Assembly |

|

|

|

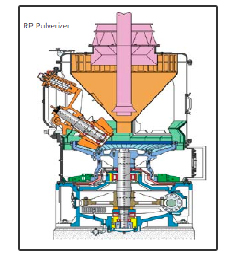

The Gear Box

|

| To prevent PF laden PA reaching the Shaft–Seal, original CE Mills were equipped with Asbestos Dust Guard Seal and a Dust Guard arrangement. |

| |

|

| This Dust Guard arrangement had a Housing in which the SA was introduced. This SA created a Pressure Chamber which prevented PF laden PA to enter the running gap between Dust Guard Seal and Dust Guard. The seal failed as the running gap increased with time. Increase in the running gap led to decrease in pressure of Seal Air in the Housing i.e. the Pressure Chamber.PA thus found its way to the Shaft-Seal taking PF with it. |

| Because the above sealing arrangement proved to be grossly inadequate, the OEM, i.e., CE, through BHEL, its then licensee in India, introduced a Mechanical Face Seal Assembly (MFS Assly). The MFS Assly seals Seal Air and not PF. |

|

|

| |

|

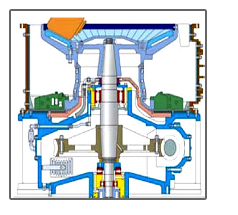

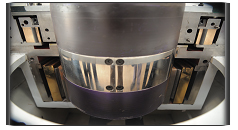

| The sealing components of this Mechanical Face Seal Assly are: |

1. Rotating Hard Face part called the “Seal Runner” which is Hard Chrome Plated,

AND

2. Stationary Soft Face part called the “Seal Assly” which has graphite sticks embedded in it. |

| These are placed in a Seal Air Housing, in turn supplied with SA to create a Pressure Chamber. However, we found that the CE/BHEL MFS Assly suffers from some gross design deficiencies. |

|

| The MFS Assly as a rule is Spring Loaded. Higher the pressure of fluid handled (Seal Air in this case) higher the Spring Loading. The Spring Loading ensures proper sealing contact between the Stationary & the Rotating parts of the MFS Assly. In case of CE/BHEL MFS Assly the Rotating Part i.e. the Seal Runner is supposed to have a sealing contact with the Stationary part i.e. the Seal Assly under its own weight/ gravity. But this does not happen because the Sealing components are NOT Spring Loaded against each other. |

| |

| |

|

|

| |

For MFS Assly to work, i.e. to have effective sealing, the sealing faces of the rotating and stationary components must be smooth and flat for a good sealing contact. In the existing CE/BHEL MFS Assly it is neither possible to achieve the ‘flatness’ nor is it possible to create it in-situ. As for the ‘smoothness’ the graphite sticks are supposed to be soft enough to offer Sealing & Lubrication, neither of which is offered in the existing MFS Assly. Copious amounts of Seal Air can be noticed in exhausts of any 623 or 763/783/803 mill equipped with CE/BHEL MFS Assly. Anything more than just a ‘bleed’ leak of Seal Air indicates that the Mechanical Face Seal Assly is NOT effective. The original CE/BHEL MFS Assly is, therefore, NOT a TRUE MFS Assly

|

| |

|

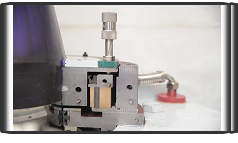

| Falcon’s MFS Assly is SPRING LOADED. Checking and correcting (with our Special Purpose Tool) the flatness of the sealing faces in situ positively and effectively is a special design feature of our MFS Assly. |

The grade and placement of graphite sticks in the Seal Assly of our MFS Assly offers a wide Sealant Lubricant band. Seal Air in Exhaust, if at all, is the ‘bleeding’ Seal Air. |

|

|

| |

| |

| Design Patented PAT #s: 196557 and 219460

|

>

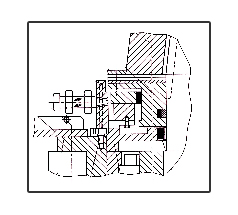

| However, the contaminants do get across the Shaft-Seal and once through, enter the Gear Box. The Rubber Seal does not fail on their own quickly. However, they cut grooves into the shaft.PF and ash/dust assist this groove formation. The pinch and profile of the seal also contribute to groove formation. To prevent or to delay this groove formation, it is desirable to have the Seal contact area on the Vertical Shaft hard and smooth. Using a Single Piece Wear Sleeve on Vertical Shaft is near impossible. Repair to damaged shafts (with grooves) is possible but not permitted on Vertical Shaft. |

| |

| |

|

Falcon’s Wear Resistant Split Sleeve is the only and the best option for use on Oil Seal Portion of Vertical Shaft. These are hardened to around 56 HRC, smooth/ mirror finished and can be replaced in situ. |

|

|

|

Design Patented PAT # 190470. |

| (It will be appropriate here to mention that the OEM provided Single Piece Wear Sleeve on ED Vertical Shaft of 623 & on Vertical Shafts of larger mills e.g. 883 & 1003 ought to have been Split, as it is very difficult to replace this groove formed Single Piece Wear Sleeve). |

Regardless, worrisome amounts of contaminants are always present in the Gear Box.

The contaminants cross the Vertical Shaft and the Rubber Seal. The

Upper / Top Radial Bearing is the first casualty. This Bearing being strong & robust gets damaged slowly but surely. It also pulverizes whatever contaminants get between the Roller and Races.The contaminants then fall into the lube oil below wrecking havoc to the Worm Wheel, Worm Gear, Thrust and Roller Bearings, and Pump attached to the lower end of the Vertical Shaft.

This Upper / Top Radial Bearing, therefore, needs constant flushing as much as it needs lubrication and the lube oil must be clean. Other than 623 mill with ED Vertical Shaft the existing system of

lubrication of Top Bearing is simple and the design is excellent. A

pump is attached to the lowest end of the Vertical Shaft. |

However, this pumped lubrication of the Top Bearing suffers from three major shortcomings.FIRST - the pump suffers a loss of capacity over time,SECOND - the pump pushes up whatever muck (including metal particles) already there, andTHIRD - the lubrication starts only a while after the mill starts.

(There are also instances where the inner race of top bearing rises (slides) up blocking the oil

outlet hole of the oil (pumped through Vertical Shaft) starving the top bearing of lube oil thus

causing the bearing to fail. The inner race, aided by the intrinsic property of rotation tends to

rise. It tends to rise when it becomes loose (on the shaft). It becomes loose when it becomes

hot. And it becomes hot when the lubrication is inadequate). |

| |

|

External filtration is one good thing happened to the life of the Gear Box internals. We provide a Centrifuge Filter for this. This filtration, however, solves only part of the problem.

|

| |

|

| |

Design Patented PAT # 1881/MUM/2010.

|

|

To flush and to lubricate the Top Bearing we offer an External Lubrication System. Filtered oil from Gear Box is pumped directly on to the top of the Top Bearing. This system, apart from offering positive continuous lubrication also keeps the bearing flushed at all times, even before the mill starts. We are working on external cooling of the filtered lube oil. |

|

|

|

|

| |

The Journal Assembly |

As in the case of Vertical Shaft/ Gear box, the Journal Assly also faces

the brunt of contamination. The cause of groove formation is the same as described earlier. The effect of contamination is also the same, but much more pronounced.

The normal procedure for the repair of such groove formed Journal Shafts is simply to undercut the shaft where grooves have formed, weld fill & machine to size. However, weld deposit being softer than |

| |

the parent material subsequent groove formation is quicker still. MTBF thus remained notoriously short.Continued/ repetitive repairs as above introduce run-outs in the shaft. Welding also introduces stresses in the shaft resulting in accelerated fatigue failure.Several procedures were tried to achieve hard and smooth surface on

the shaft where the Rubber Seal is in contact. Providing a Single Piece Wear Sleeve was an option and tried at several places. But these Single Piece Sleeves have not proven satisfactory.

Single Piece Sleeve, necessarily Shrink Fitted, necessitates removal of

bearings during first and subsequent replacement fitments, almost always resulting in damage to seating portion of the Sleeve and the bearings, and often to the bearings themselves. The Single Piece Sleeve has three other inherent draw backs.

ONE – it tends to rotate around the shaft,

TWO – it tends to slip from its position, and

THREE – it becomes a once use and throw type part |

| |

(The OEM, some time ago, obviously to overcome the second drawback as above,

incorporated a Single Piece Wear Sleeve ON a modified Journal Shaft. The Sleeve is introduced

from the top i.e. from taper (Journal Head) side of the shaft. The sleeve is shrink fitted. The

first and the third drawback remain unaddressed and new problems are added. Seal size has

changed leading to keeping separate identified inventory plus the bother to log as to which

(out of 3) Journal Assly has such modified Journal Shaft and Seal and in which of the mills). |

| |

|

Our Wear Resistant Split Sleeve came into being and has been very well received. We make these in EN-31/ SAE 52100 material with surface and through Hardness of around 56 HRC. Surface is ground smooth with an option for a mirror finished surface. With chosen placement position and its width our Split Sleeve is Reversible, for use twice over. First, reversed & replacement fitment is easy and quick. MTTR is, therefore, very short and vastly extended MTBF is achieved. |

|

| |

Design Patented PAT # 190470. |

|

All products above are applicable primarily for XRP 623, 763/783/803 mills. We have supplied our MFS Assly for several XRP 883 mills. Our specially designed MFS Asslys for Stein France Mills (No. BCP 2360/77 which have planetory Gear Box and a Vertical Shaft) at Gandhinagar are hugely appreciated and have saved the plant several hundred million Dollars. We are ready with our MFS Assly for XRP 623 with ED Vertical Shaft & XRP 1003 mills. |

| |

| |